Upgraded smoltification test gives Mowi greater confidence in salmon transfers

A novel gill-tissue diagnostic technology — supported by rapid laboratory analysis — has enabled salmon-farming giant Mowi to much more precisely gauge when to transfer its smolts to sea cages within its Pacific West Coast operations, ensuring that the fish get off to a good start in the saltwater phase of grow-out.

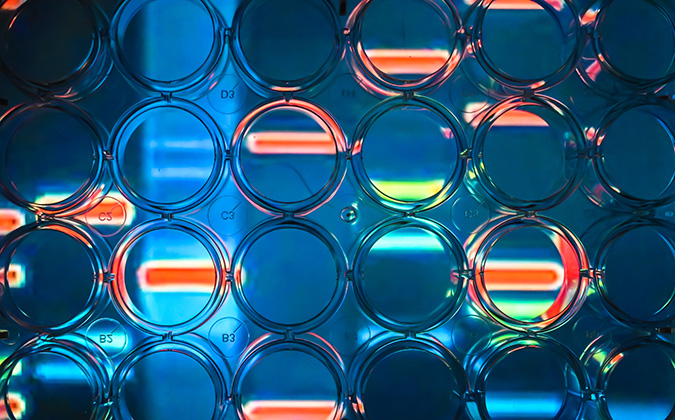

The technology, SmoltVision, is a real-time polymerase chain reaction test commercialized by PHARMAQ Analytiq. It measures genetic markers in gill tissue that are directly related to adaptations taking place in the gills of the fish during smoltification, the process by which salmon prepare to transition from freshwater to seawater. In addition to measuring the genes that regulate the freshwater and saltwater isoforms of the enzyme ATPase, it evaluates the expression of an additional cofactor gene that is an indicator of gill health.

Mowi, which has three sites in Canada producing around 10 million smolts annually, started sending samples from its SmoltVision tests to a laboratory in Montreal in October 2020, with the trial continuing through December. Consequently, samples from almost every cohort of fish that has gone to sea during and since — essentially the whole year class — has been tested with the tool.

‘SmoltVision puts the manager in control’

Knowing the status of your smoltification process is key for any business that’s farming salmon, Juan Carlos Sanchez Millar, freshwater director, Mowi Canada West, told Fish Health Forum.

“The main reason for this is that it’s a very susceptible stage for the fish; they’re going from an environment that they have known all their life into vast and unknown ocean surroundings,” he said.

They need to be put to sea at just the right time, and because this optimal transfer window amounts to only a certain number of days, it’s important to have and to use the tools that are available to help identify that ideal opportunity. “SmoltVision puts the manager in control,” enabling them to make that decision, Sanchez said.

“If you use another tool that is less specific than SmoltVision, for example, it’s possible that you can be misguided.”

Quick lab turnaround is ‘game-changer’

According to Sanchez, having a trusted laboratory in Canada has been a “real game-changer” in this scenario as it provides fast turnaround. Otherwise, it can take as long as 10 days to get results when sending samples across the border due to customs clearance and other factors.

With the whole smoltification process lasting between 3 and 4 weeks (from zero to 28 days), it would be acceptable to send samples from week 1 and 2 and get the results back up to 10 days later, he explained. But for week 3’s sample, a much quicker turnaround would be needed to respond effectively.

“While the smoltification window is temperature dependent, it’s still usually between 7 and 10 days, during which time, the fish are good to go. But if you transfer too late, after those 10 days, it could be detrimental to the salmon. You could have some mortalities, or they might not feed very well once they get out to the ocean. Now, though, if we are sending samples to the Montreal lab today, we are getting the results tomorrow or the day after. That’s something that we can really work with.”

Getting specific

Another benefit of SmoltVision is its specificity with respect to the breakdown between freshwater and saltwater isoforms of ATPase, Sanchez added.

“We can see the change in enzyme proportions between weeks 1, 2, 3 and 4 — starting with a high freshwater expression and gradually moving toward the ideal 75% to 80% saltwater expression. We want that high saltwater expression in the last week — not when we start because we’ve still got to wait 3 or 4 more weeks before transfer,” he said.

“We trust the test; we have gained a lot of confidence from using it. Alongside other changes that we’ve made to our operations, we are seeing the positive results out at sea,” he said.